Applications

Temperature Control Unit

-

General characteristics

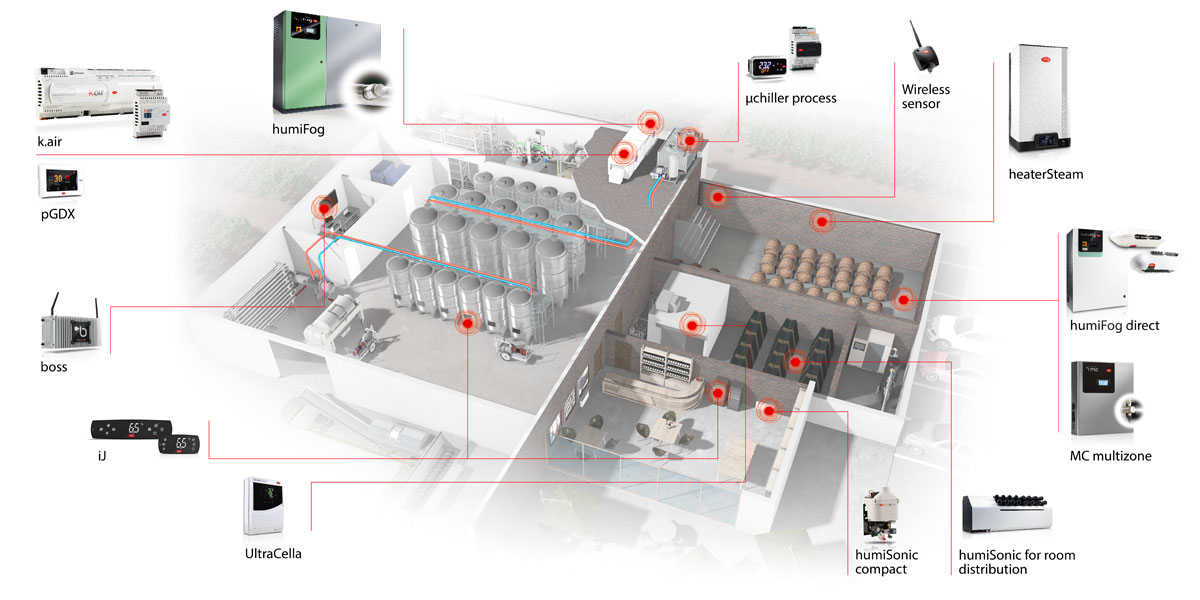

A temperature control unit (TCU) (also called “temperature controller”) is typically used to preheat an industrial process and maintain the desired temperature.

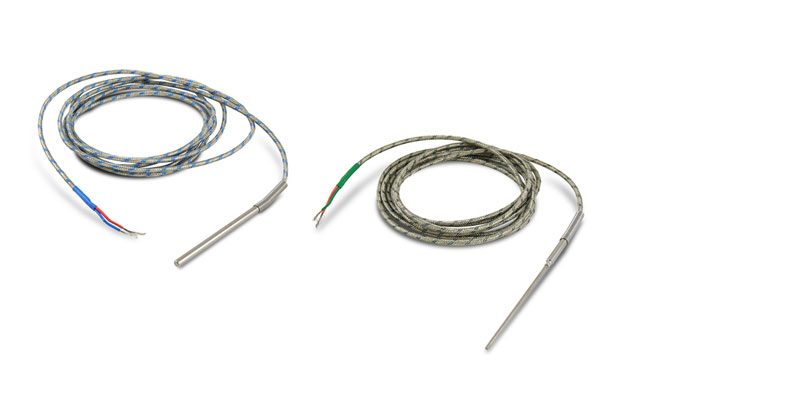

A TCU works by using an electric heater, either immersion or continuous, to heat the fluid in the system, then circulating it from the TCU to the machine tools and vice-versa. The fluid used may be water, pressurised water or oil, depending on the temperature range. Usually this is water if T < 95°C, pressurised water if T< 150-160°C and oil for T from 200 to 400°C.

Once having reached the set operating temperature, the unit can continue to heat the fluid, or alternatively may act as a cooling system. If the fluid used in the TCU is water, cooling is performed by adding fresh water (direct cooling), while if the fluid is pressurised water or oil, a fluid-water heat exchanger is used (indirect cooling).

The cooling water is precisely measured and metered via a valve, which may feature modulating operation, and is usually supplied by a chiller.